Last Update November 2019

Hardness Reduction and Removal through Ion Exchange

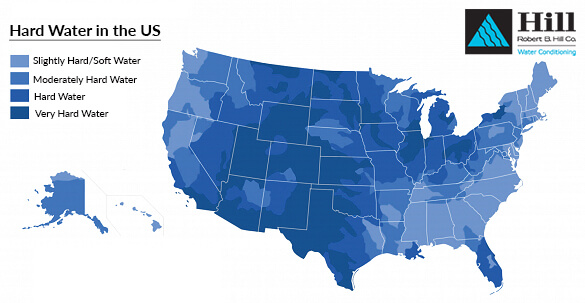

Hardness in water is found throughout the world and can cause a wide variety of problems. In Fact, 85% of America has hard water. The problems that can occur are mainly scaling which reduces efficiency on water heaters, boilers, cooling towers, and many other processes.

Water hardness is composed of calcium (Ca) and magnesium (Mg). To reduce or eliminate hardness from the water, there are various processes that can be utilized. The most common is the use of water softeners which exchange the calcium and magnesium for sodium. This technology is used in residential, commercial and industrial settings.

In industrial and municipal applications, lime softening can be used with clarifiers and the addition of lime. The calcium and magnesium precipitate out of the water and form sludge at the bottom of the clarifier. Due to the advancement of membrane technology, Nanofiltration, or NF, can be used as well. This publication will mainly discuss how water softeners work due to the process of ion exchange.

How is Hard Water Measured?

Water hardness is measured in grains per gallon (gpg) and in part per million (ppm) or milligrams per liter (mg/L). One grain per gallon is equal to 17.1 ppm or mg/L. Below is a classification of water hardness.

| Soft Water | 0 to 3.5 grains per gallon | 0-60 ppm |

| Moderately Hard Water | 3.5 to 7 grains per gallon | 61-120 ppm |

| Hard Water | 7 to 10.5 grains per gallon | 121-180 ppm |

| Very Hard Water | Over 10.5 grains per gallon | Over 180 ppm |

Water can be tested using water hardness kits such as test strips, titrates, and various digital handheld testers. Once the hardness is known, one is able to calculate the capacity of the cation exchange resin. Capacity is determined by water hardness, salt dosage and the amount of cation resin used. Salt dosage equals the following capacities in grains.

| 6 lbs. of salt per cubic foot of resin | 20,000 grains |

| 8 lbs. of salt per cubic foot of resin | 22,500 grains |

| 10 lbs. of salt per cubic foot of resin | 25,000 grains |

| 12 lbs. of salt per cubic foot of resin | 27,500 grains |

| 15 lbs. of salt per cubic foot of resin | 30,000 grains |

How Much Resin Will I Need?

Now that we know how hardness and salt dosages are calculated, we can figure out cation resin capacity by cubic foot. Below are simple equations that are used. We will assume 10 lbs. of salt per cubic foot of resin along with 25 grains per gallon of hardness.

25,000 grains/hardness of 25 gpg = 1,000 gallons of softening capacity If we used 10 cubic feet of resin, the same equation would be used except that 25,000 grains would be multiplied by the number of cubic feet of resin. 10 cubic feet of resin * 25,000 grains/hardness of 25 gpg = 10,000 gallons of softening capacity.

The reason these calculations become imperative in water softener applications is because it affects the design of the equipment. The above calculations do not take into account flow rate, only capacity, but are the basis of the beginning of water softener design. The size of the water softener is dictated by the capacity. It does also include flow rate calculations, but for now, the size and capacity are solely related.

Industrial water softeners have a given capacity that we discussed above. Once that capacity is exhausted, a water softener must regenerate or the resin would have to be continuously replaced. Because this is almost always unfeasible, water softeners must regenerate using salt. The regeneration process consists of backwash, brine draw/slow rinse, fast rinse and refill.

Backwash is controlled by a backwash flow control orifice. Standard backwash velocity should be 5 gallons per minute (gpm) per square foot of bed surface area. In backwash, the resin bed is expanded through reverse flow to remove organic matter and any particles that have accumulated on the resin beads. Brine draw is next which draws brine into the resin bed in the same direction as the service water flow.

The brine is from a nearby brine tank, brine pit, or day tank of a salt silo. During brine draw, the cation beads are recharged to attract calcium and magnesium to its core which it exchanges with sodium ions. The rate of brine draw is controlled by a venturi or a brine pump. While the brine is being drawn into the resin bed, freshwater is used as well to dilute and help distribute the brine flow evenly over the bed. After the brine draw is complete, which is controlled via an aircheck or by time, slow rinse starts.

In slow rinse, freshwater is used to rinse approximately 80% of the brine water out of the bed. The next step is a fast rinse. In fast rinse, the velocity of the flow is the same as backwash but is in the same direction as service, which packs the bed back down to its service position and also rinses the remaining 20% of the brine water. The final step is refill. Because all of the brine has been removed from the brine tank, it has to be replenished. To replenish it, freshwater is sent back through the same piping that the brine draw occurred. Refill is controlled by a brine line flow control and is programmed to refill by time.

What Type of Design do I Need?

Depending on the application, water softeners are designed in several ways. For residential and commercial applications, the most common design is a fiberglass pressure vessel with a top-mounted valve. This is typically the most cost-effective design for equipment and installation costs. The main limitation of this design is that it is not able to handle high flow rates.

For higher flow rates, the most common design is a valve nest with steel pressure vessels. Instead of using a top-mounted valve, six valves are used instead. This design allows for less pressure loss and is used in commercial and industrial applications. Valve nests are much more robust and have fewer mechanical failures compared to top-mounted valves when they are used on a continuous basis.

Contact a Professional

We hope that this information is helpful for those looking to research a water softening solution but we understand it is a lot of information. Robert B. Hill Co has been in the water treatment business for over 60 years and we would love to help you find the best application for your building. Contact us today and one of our licensed water treatment professionals will help you determine a water softener that fits your needs.